Blog

Our property hosts a quite old (50+ years) shearing shed. In desperate need of repair we decided to renovate and repurpose. The sheep are long gone and goats don't need shearing so its now a fully functioning off-grid work area.

The Shearing Shed

Our shearing shed was overrun by possums, rats, swallows and was essentially a small eco-system of its own. With one back wall all but disintegrated it was too much of a nice building to let fall into ruin. It also forms part of the history of our property and Chudleigh itself. Given our house was built sometime around 1836 it was one of the first farming properties of the area. It took a good 18 months to fully renovate and was a self-build project. Being quite a large shearing shed of around 18 x 12 metres it is physically a large space. To make things harder there was not a single square corner or flat surface so a lot of custom repairs and fitting had to be undertaken. The goal was to build a completely sealed open plan space to function as an off-grid office and work area that could be heated so it could be used year round. A few years on and it has certainly met all of those goals. The power system is a good example of an off-grid solution so here is what it is comprised of.

The Batteries

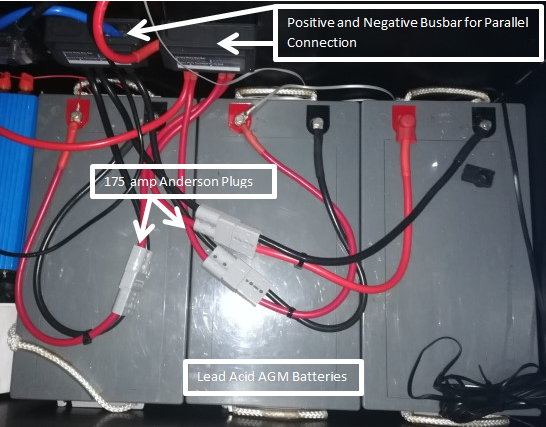

We have three 280ah Lead Acid AGM batteries that are about five years old and still going strong. The batteries live inside of custom built cabinet that sits on wheels so it can be moved around if necessary. Each battery is connected in parallel using 175 amp Anderson Plugs to common positive and negative busbars. In our view the best method for connecting two or more batteries in parallel is to use a common busbar. This reduces any potential issue with balancing that can occur when stringing large numbers of batteries in parallel. Total theoretical battery capacity is therefore 840ah however given the batteries are now five years old this will be somewhat less. So in theory this would be considered a 10kWh storage capacity. Taking into consideration usable capacity of say 50% this would therefore be 5kWh. At most per cycle we only use between 1-2 kWh and at this consumption voltages do reflect a slight ageing of the batteries but still in the good health range.

Eventually when these batteries reach the end of their serviceable life they will be replaced with LIFEPO4.

The components used -

- Busbar - 2 x 500 amp busbars

- Battery - 3 x 280 ah Lead Acid AGM Chemistry

- Connectors - 3 x 175 amp Anderson Plugs

- Wire - 2B&S DC

Solar and Wind

The shearing shed batteries are charged using three 275 Watt panels connected in parallel. Normally the panels would be connected in series however in this case the charge controller has limited voltage input capabilities. Additionally there are two wind turbines that feed the system being a 400 Watt and 600 Watt turbine.

The components used -

- Solar Panels - 3 x 275 Watt

- Charge Controller - Enerdrive DC to DC 50 Amp MPPT

- Breaker - 50 amp DC breaker

- Wire - 6mm2 from panels and 16mm2 from controller and turbines.

- Wind Turbines - DB-600 and no name brand 400 Watt turbine (actually very good).

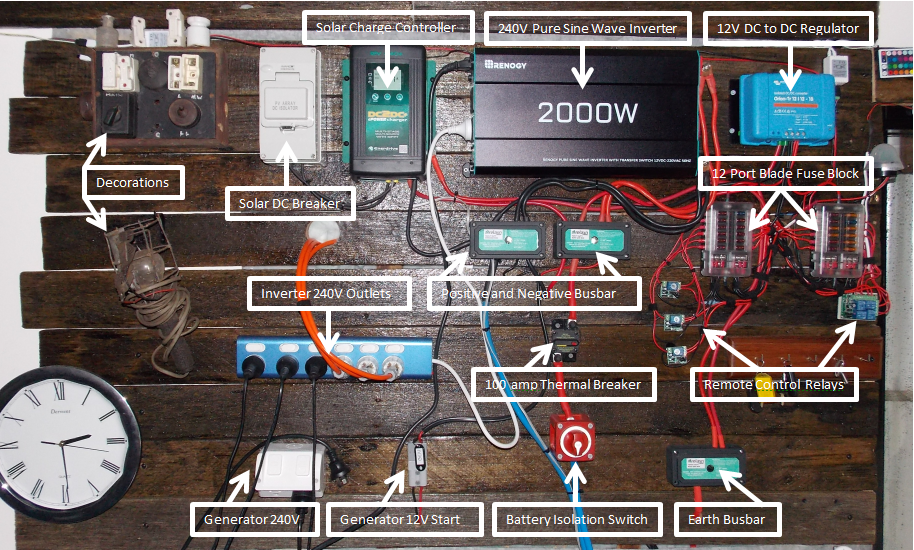

The 12V and 240V System

The shearing shed 12V system is supplied using a regulated output from a Victron Orion DC to DC Converter (12V - 12V). The purpose of using a regulated 12V supply from the batteries is to ensure consistent voltage so battery voltage does not affect things like light brightness. The Victron Orion we use has a maximum output of 220 Watts. This provides power to all lighting and 12V/USB sockets throughout the shed. A 2kW Renogy pure sine wave inverter with mains automatic transfer switch is used for all 240V supply. If the generator is started all 240V power is automatically switched to the generator circuit. When the generator is turned off it automatically switches back to battery supply. Whilst the generator is rarely used it is generally turned on when really heavy loads are required. The shearing shed provides full-time power for:

- 12V Lighting

- 12V Diesel Heater

- 240V Chest Freezer

- 12V/240V Large Camping Fridge

- 240V and 12V Outlets

Heating

We use a 5kW rated diesel heater that is installed externally to the shearing shed and blows hot fresh outside air in. This is by far the best and most economical form of heating we could find and it does work extremely well. Heater controller is wired into the shearing shed. Once ignited diesel heaters use very little power making them perfect for off-grid use.

If you are looking at setting up your own battery system but aren't sure what you need why not contact us? We can provide a consultation service to get you on the right track.

Comments

- No comments found

Leave your comments